Scope of Products

Completed Operation-Integrated Production

Beginning from the designing draft offered by clients, the company is able to assist with the introduction of product design of die-casting molds and production concept. The integrated production, includes the suggestion of material uses, mold design, mold-making, mold-testing, finished product castings, burr treatment, scrap pressing, drilling/tapping, CNC processing, coating, positive pole treatment, and printing, is now available with good planning and service.

The company welcomes clients for small volume and wide variety of magnesium, aluminum, and zinc die-casting mold design and production, plus the completed operation of metal product manufacturing.

As part of efforts in the world-wide environmental protection, the company has now abided by the RoHS green environment requirements. This expects to serve as the duty of enterprises in the protection of the earth.

Merits

- Effectively controls delivery date and quality.

- Reduces R&D and production cost.

- With their well-trained and years of experiences, our technicians are able to offer all kind of solution packages for customers.

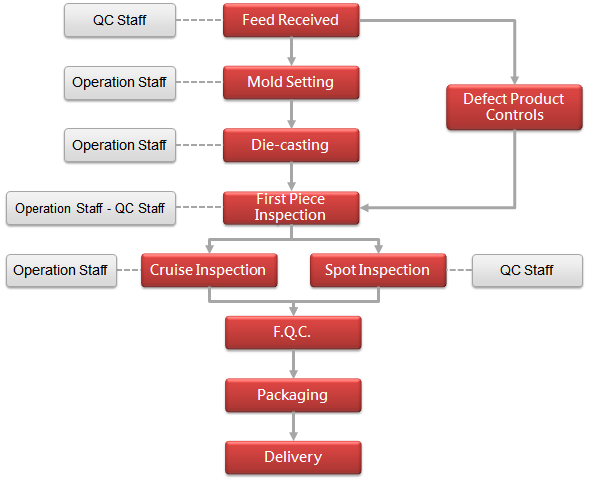

Production Flow Chart